HYDROGEN EMBRITTLEMENT 0f STAINLESS STEELS (Part 1) – Gene Sheldon

Hydrogen embrittlement is one of a number of ways that hydrogen causes damage to metals such as hydrogen induced blistering, cracking due to hydride formation, precipitation of hydrogen in the metal leading to internal cracking, to name a few. This discussion will be specifically about hydrogen embrittlement, what materials are susceptible to hydrogen embrittlement, and what factors affect material susceptibility to hydrogen embrittlement.

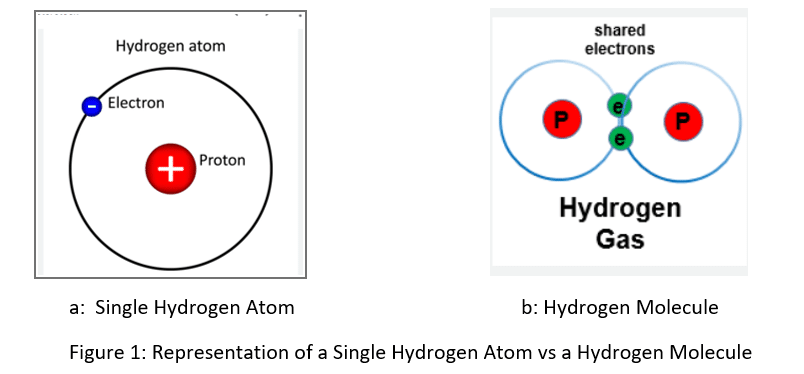

Hydrogen embrittlement as the description implies is that hydrogen makes metals less ductile. For this to happen the material needs to absorb hydrogen and be under stress (either applied or residual stress). However, metals can only absorb hydrogen when it’s a single atom (Figure 1a). Normally hydrogen gas is made up of molecular hydrogen (two hydrogen atoms that are bonded together Figure 1b) which are too big to be absorbed. The situation that creates hydrogen atoms and exposes material to these hydrogen atoms are processes such as electroplating, or corrosion in acid solutions.

When metals absorb hydrogen the metal’s elongation and yield strength are reduced resulting in failures at lower loads. For example, if a one-inch diameter rod of high-strength steel has a yield strength of 190ksi it can carry a load of about 150 lbs without deforming for years. However, if that same material is placed in an environment that causes hydrogen embrittlement (seawater), and if a load of 95ksi (50% of yield strength) is applied to the material it can fail in a few hours.

The first thing to determine is what materials are susceptibility to hydrogen embrittlement, and why are they susceptible. Studies have shown that materials with a yield strength of over 150ksi are susceptible to hydrogen embrittlement. This includes high-strength steels, precipitation-hardened stainless steels, austenitic stainless steels, and martensitic stainless steels to name a few. Materials with high yield strength can be produced in a number of ways. The composition of the material, how it’s processed, or a combination of composition and processing can produce materials with high yield strengths.

An example of the effects of chemistry on mechanical properties can be seen in martensitic stainless steels. These stainless steels are hardenable alloys composed of iron and chromium, for example S410 is composed of 12.5% chromium, 0.12% carbon, the balance is iron. These alloys can be strengthened by heating them to a certain temperature, cooling them quickly, and holding them at a lower temperature for some period of time. This procedure produces hardened and tempered material. In the annealed condition the tensile strength would be 75ksi, the yield strength 45ksi, and the elongation 35%. The yield strength of this material would be below the 150ksi yield strength that promotes hydrogen embrittlement. However, in the hardened and tempered condition, the tensile strength could be around 220ksi, the yield strength 177ksi, and an elongation 14%. Well above the 150ksi yield strength, which would indicate this material would be prone to hydrogen embrittlement.

The combination of chemistry and processing (rolling for example) can determine the strength of the material. In austenitic stainless steels, the amount of nickel determines how strong the material becomes when it is rolled.

| Mechanical Properties of Annealed S301 and S305 Austenitic Stainless Steels | |||

| Alloy | Tensile Strength | Yield Strength | Elongation |

| S301 | 110ksi | 40ksi | 60% |

| S305 | 85ksi | 38ksi | 50% |

Mechanical Properties of 50% Rolled S301 and S305 Austenitic Stainless Steels | |||

| Alloy | Tensile Strength | Yield Strength | Elongation |

| S301 | 252ksi | 245ksi | 3% |

| S305 | 155ksi | 140ksi | 5% |

Table 1 Above: Mechanical Properties of Annealed and Rolled to Temper S301 and S305 Stainless Steels

In Table 1 a comparison of the annealed mechanical properties of the two stainless steels were quite close, though the S301 material properties were slightly greater than the S305. In both cases, the yield strength was way below the 150ksi threshold. However, when the thickness of each of the materials were reduced by 50% the S301 yield strength increased by 6 fold to 245ksi indicating it would be susceptible to hydrogen embrittlement. The yield strength the S305 material increased as well to 140ksi, but below 150ksi which would indicate the material would not be susceptible to hydrogen embrittlement.

The lower nickel content of the S301 allows the formation of an internal structure when deformed, and significant residual stresses increasing the material susceptibility to hydrogen embrittlement. The higher nickel content of the S305 does not allow the formation of the structure produced in the S301, so susceptibility to hydrogen embrittlement would be less. However, the residual stresses due to the rolling operation may result in a decrease in the yield strength load in a hydrogen embrittlement situation.

In future installments how the internal structure of materials affect hydrogen absorption will be discussed. If you have any questions or comments please feel free to contact Gene Sheldon for more information here at CONTACT US Simply add #AskGene to the subject of your request.